Precise Valve and Process Equipment Sizing

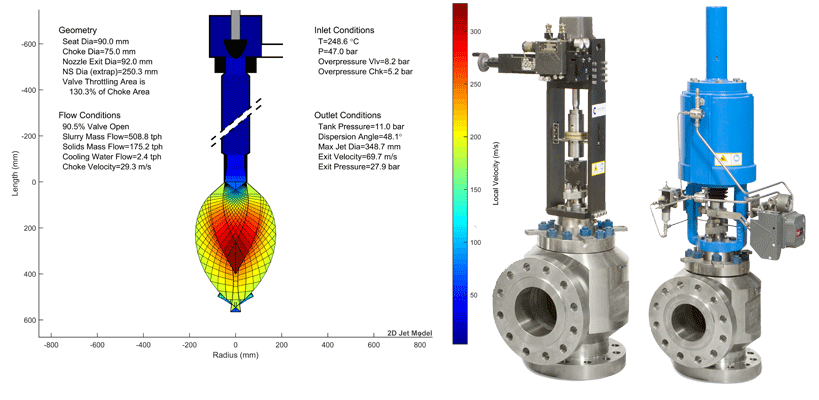

Caldera uses its proprietary CalPhlash™ modeling engineering services to accurately determine optimal valve and choke sizes for plant-critical flow control equipment in flashing applications. Standard industry calculation techniques can be acceptable, but they don’t always lead to the optimal configuration, as they do not account for energy released during the phase change of water to steam.

When a valve or choke is not sized correctly, it can lead to problems upstream and downstream of the equipment which can be very expensive to fix. Caldera’s CalPhlash™ modeling engineering services help avoid those costly errors.

Caldera's Modeling of Flashing Flow Includes

- Optimal bore size of valve and / or fixed choke

- Supersonic compressible flow through valve seat and blast tube

- Spray pattern of slurry as it enters a flash vessel

- Organizing of inputs / outputs for multiple cases

- Outputs for detailed design as well as visualization (including graphs, plots, and videos)

- Thermodynamic fluid properties

Caldera uses an analytical approach to size equipment correctly the first time rather than an iterative approach of trialing parts to converge on an acceptable solution. With Caldera, you get precise, purposeful sizing to prevent plant disruptions and avoid costly shutdowns.

To learn more about how Caldera’s valve and equipment sizing of flashing flows can improve the performance of your site and prevent costly shutdowns call us at 801-356-2862.

Email us, and one of our engineers will review your questions and concerns and get back to you within 24 hours. Contact us here.