In-line chokes are positioned in series at choke stations within slurry transport pipelines that drop in elevation. These ceramic-lined chokes drop the pressure by restricting the flow area which dissipates the energy from the elevation head.

Customized Design for Specific Needs

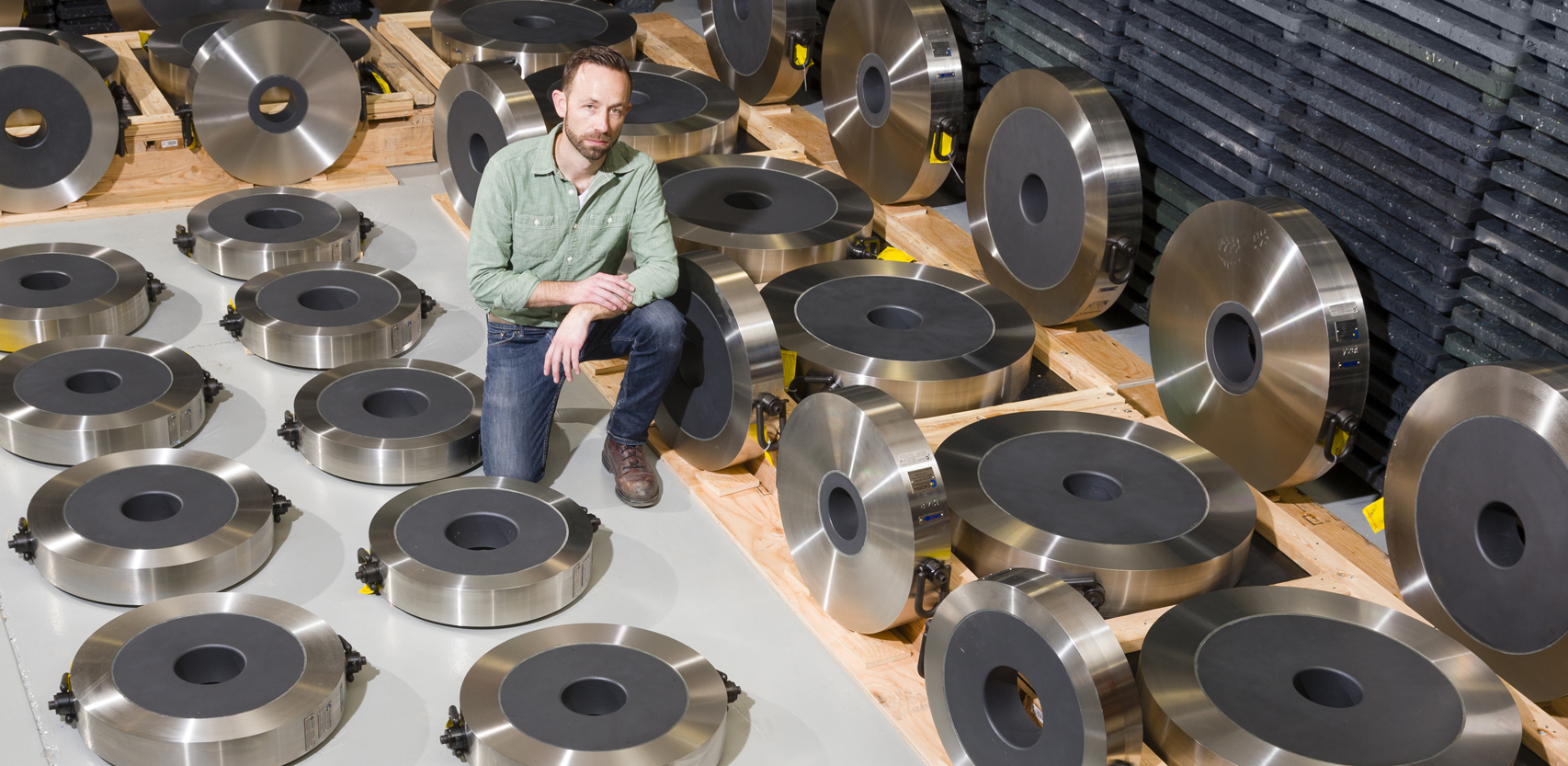

Caldera custom designs in-line chokes specific to customer needs in size, pressure class, and materials. Caldera has supplied in-line chokes ranging in size from 6 to 30 in (DN 150 to DN 750) and pressure classes 150 to 1500. Caldera has tools to properly determine an orifice size for a required pressure drop. Caldera can also verify that the thickness and features in the housing are adequate to support the ceramic for the required pressure drop across the in-line choke.

Application-Specific Materials

Caldera utilizes different grades of silicon carbide ceramics (reaction bonded, nitride bonded, and sintered) depending on the choke size and slurry conditions. Caldera works with different metals (e.g. carbon and stainless steels) for the housing materials which are also dependent on the process conditions. Retention of the ceramics within the metal housings is accomplished with mortars or resins best suited to the specific operating conditions.

To learn more about Caldera’s in-line chokes call Caldera at 801-356-2862.

Email us and one of our engineers will review your questions and concerns and get back to you within 24 hours. Contact us here.